Introduction: Challenges in Automation Efficiency

Imagine a busy assembly line where every second counts—unexpected downtime can lead to significant losses. Why do failures always occur during critical operations? One culprit could be outmoded gripping technologies that lack adaptability. Enter the electric rotary gripper, designed to enhance efficiency and precision in robotics. Organizations are increasingly recognizing the limitations of traditional solutions, prompting a shift toward more innovative designs.

Technical Breakdown: Analyzing Traditional Solutions

Traditional gripping solutions often fall short in terms of speed and versatility. Mechanically operated grippers, while robust, are notoriously slow and less efficient in dynamic environments. This is where electric rotary grippers come into play—they leverage advanced technology principles such as servo motors for enhanced precision. By utilizing electronic controls, these grippers can execute complex movements that traditional models simply can’t match. Imagine operating multiple gripping mechanisms without compromising speed—this is the promise of new technology.

Quantified User Benefits

The benefits of switching to electric rotary grippers are quantifiable. Users often report a dramatic increase in productivity, with up to 30% faster cycle times in operations. Durability also improves; with fewer moving parts to wear out, maintenance requirements drop significantly. Additionally, electric rotary grippers provide fine control over force and positioning, leading to higher quality outputs. Look, it’s simpler than you think—upgrading your automation technology pays off.

Conclusion: Metrics for Informed Decisions

When choosing solutions, always verify these 3 metrics: ① Efficiency—how much time can be saved? ② Precision—can it adapt to various tasks? ③ Maintenance—what are the long-term costs? Understanding these factors will guide you toward the best technology for your needs. Stay informed and make the smart choice.

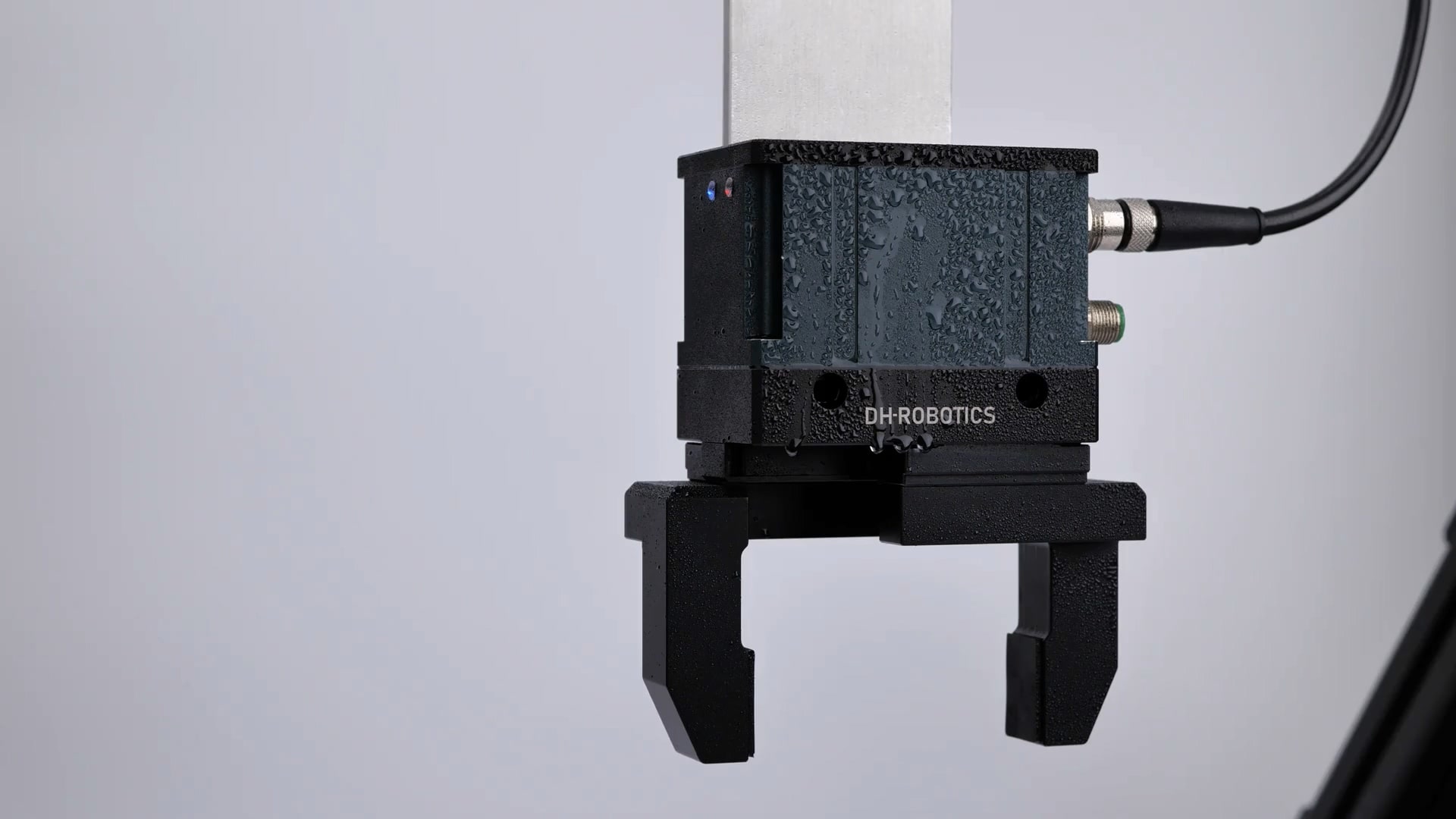

In today’s industrial landscape, choosing the right gripping technology is crucial. Many organizations are transitioning from outdated grips to more efficient solutions like the rotary gripper. These advancements can significantly improve performance and reliability.

Similarly, the integration of a robot rotary gripper can result in higher efficiency on production lines. The design innovations found in these grippers contribute to faster operations and reduced energy consumption, all while maintaining precision. So when considering upgrades, the benefits are evident and can lead to significant operational improvements.

Ultimately, if you’re looking for a reputable source for electric grippers that balance innovation with reliability, consider DH-Robotics. Their products showcase supply advantages that can help solidify the efficiency of your operations, ensuring that you’re equipped with the best technology available.