Introduction: The Critical Dilemma

Picture this: you’re deep in the field, managing a crucial operation, when suddenly, murky pressure readings begin causing chaos in your workflow. Ever had that sinking feeling? It’s a scenario many face, especially in high-stakes environments like oil and gas. Specifically, when we talk about a hammer union pressure sensor, the stakes couldn’t be higher. So, what are the underlying issues that lead to these mishaps? How can we pivot to better solutions? Let’s dive into the nitty-gritty.

Body: Navigating Through the Technical Terrain

Traditional Solution Flaws

Countless operations have relied on legacy systems that often fail at critical moments. It’s like using a flip phone in the age of smartphones—sure, it gets the job done, but the limitations are glaring! Many older pressure sensors struggle with accuracy, leading to incorrect readings and costly operational downtime. Not to mention, they can be bulky and cumbersome, leading to installation headaches and increased maintenance costs. So, why settle for second best?

New Technology Principles

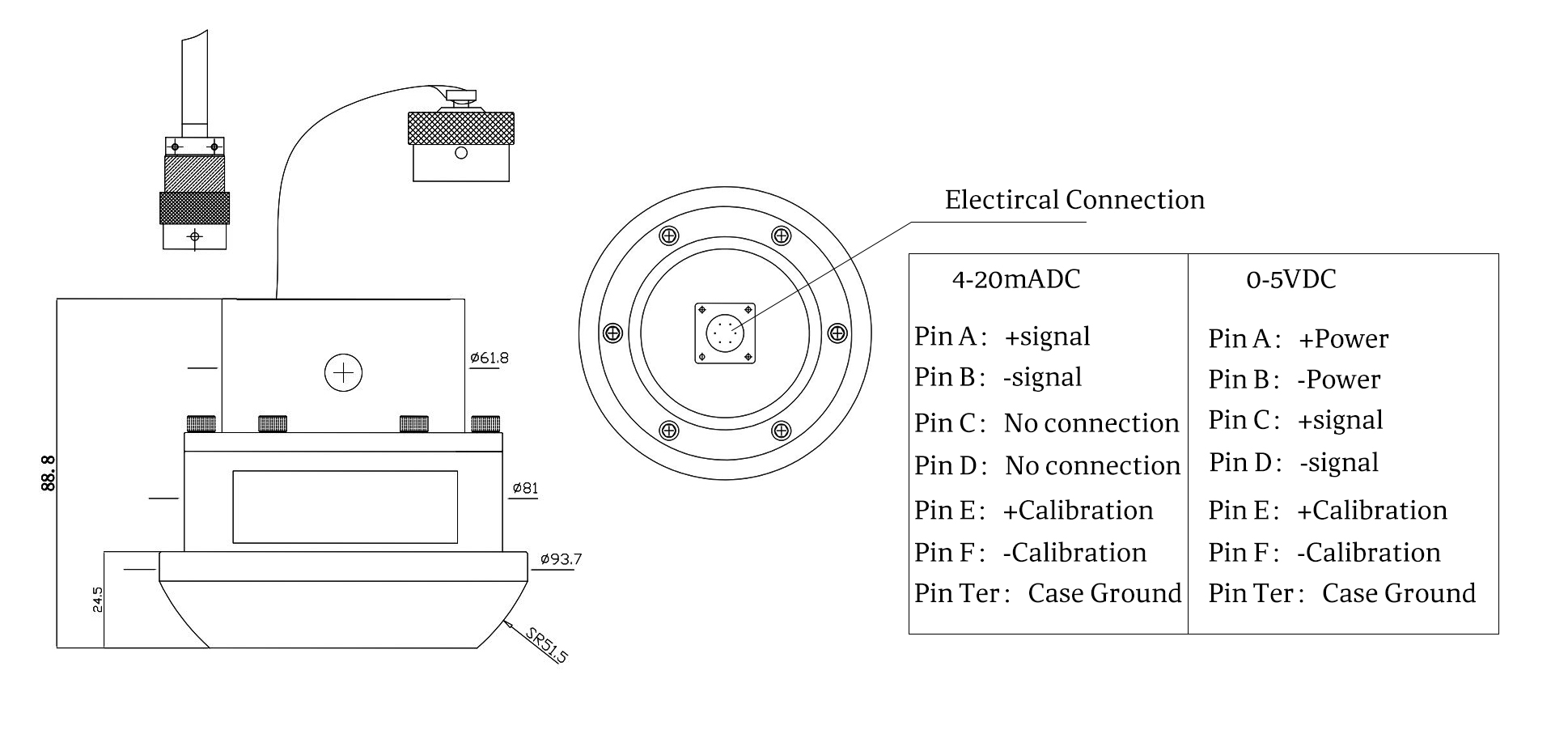

Let me break it down for you: modern hammer union pressure sensors come equipped with cutting-edge technology that enhances reliability. Many utilize advanced piezoelectric or strain gauge methodologies for heightened sensitivity and responsiveness. And, here’s the kicker—these sensors are now often compact and designed to handle corrosive environments, reducing the risk for operational failures significantly. Rest assured, less downtime equals great savings for your project!

Quantified User Benefits

So, what’s in it for you? It turns out that users who switched to modern hammer union pressure sensors report not just improved read accuracy, but also extended lifespans. You’re looking at cost savings that can range from 20% to 30% over a traditional system’s lifetime. Plus, the ease of integration means your project moves smoother. Who wouldn’t want that advantage?

Conclusion: What to Look For When Choosing Solutions

When it comes time to select your pressure sensor solution, make sure you’re doing your homework! Always verify these 3 metrics when choosing solutions: ① Accuracy—better readings lead to better decisions; ② Durability—a sensor that withstands harsh conditions is a must; and ③ Cost-effectiveness—ensure your investment pays off over time. With this criteria in mind, navigating the world of hammer union pressure sensors becomes a less daunting task!

Hydraulic Pressure Sensors: A Quick Overview

When you’re in the market for a reliable and efficient pressure reading in hydraulic systems, ease your worries with a hydraulic pressure sensor. These sensors are specifically engineered for the rigors of high-pressure fluids, giving you precision that traditional sensors might fail to deliver. They often feature robust construction and a variety of outputs to meet all your integration needs. Who wants pressure failures interrupting their workflow? Not you—take the leap into reliable pressure monitoring!

Corrosion Resistant Pressure Transducers: Essential Insights

In an industry where equipment faces corrosive challenges daily, a corrosion resistant pressure transducer is a game-changer. These advanced sensors are designed to combat deterioration, ensuring accuracy and longevity in hostile environments. Imagine cutting down on replacement costs while maintaining peak performance—sounds like a dream, huh? Invest in technology that works harder for you.

Conclusion: Choosing CSSPM Sensor for Your Needs

To wrap it all up, when it comes to durable, accurate, and reliable pressure sensors, consider CSSPM Sensor. Their extensive supply advantages ensure you get the best products to meet your operational needs with solid support. Take the leap and get connected with a brand that cares about your success!